Mixed Fermentation

- This article is about sour brewing methods using commercial cultures. For other sour brewing methods, see Brewing Methods.

Contents

Introduction

For the purposes of this article, we are defining a mixed fermentation as any fermentation that consists of a combination of Saccharomyces, Brettanomyces, Lactobacillus, and Pediococcus cultures. Broadly speaking, there are two styles of mixed fermentations: "sour" fermentations and "funky" fermentations. "Sour" fermentations are characterized by their higher acidity and tart flavor, and require the use of a Lactic Acid Bacteria (LAB; generally Lactobacillus and/or Pediococcus). "Funky" fermentations generally do not contain LAB, but instead use a combination of Saccharomyces and Brettanomyces. Funky beers may be slightly tart, but are generally not considered sour. For both categories, the primary fermentation will be completed by yeasts such as Saccharomyces and/or Brettanomyces. For Funky Mixed Fermentations, see the Funky Mixed Fermentations page. For 100% Brettanomyces fermentations, see the 100% Brettanomyces Fermentation page.

It is important to mention that sour brewing in general has very few well-established "rules". Many methods can be used in conjunction with other Brewing Methods, and new methodologies are constantly being developed. Many of the methods used are determined by the types of microbes the brewer is working with. An article of this length cannot encompass all mixed fermentation methods. Instead it will provide a "big picture" view of the general methodologies. More detailed information can be found in Michael Tonsmeire's pivotal book on sour brewing, "American Sour Beers". The full range of methods described in his book probably won't make it onto this wiki.

Sour Mixed Fermentation-The Basics

Sour fermentations require at least one Lactic Acid Bacteria (LAB), such as Lactobacillus or Pediococcus, and at least one yeast such as Saccharomyces or Brettanomyces. Many yeast companies offer Mixed Cultures that provide all of the microorganisms necessary to make a sour beer. The results of these commercial mixed cultures can be as varied as the cultures themselves. For example, some of these commercial mixed cultures produce lightly tart beer that may exhibit minimal funky flavors; others may produce intense sourness and assertive funk. This is dependent on the types of microbes in the mixed culture, their ratios, how old the cultures are, and what methods the brewer uses to encourage or discourage certain flavors. The brewer must understand that all of these microbes are complex organisms (some more complex than others). Not only do different species behave differently and produce different results under different conditions, but different strains of the same species also can also behave differently and produce different results under different conditions. Just as strains of Saccharomyces cerevisiae produce different results in clean beers (e.g., California Ale yeast versus Belgian Ale yeast), strains of Lactobacillus spp. and especially Brettanomyces spp. can also vary widely.

Beer styles that can be brewed using this method include Berliner Weissbier and the subcategories of American Wild Ale, which include Mixed-Fermentation Sour Beer and Soured Fruit Beer [1]. European sour styles such as Lambic, Gueuze, and Fruit Lambic, technically can only be produced by Spontaneous Fermentation. Flanders Red Ale and Oud Bruin styles can be brewed using pure cultures, but can also be brewed using spontaneous fermentation or a mix of using pure cultures and spontaneous fermentation.

Traditional Method –Long Fermentation

The most basic method for making a mixed fermentation sour beer is to brew some simple wort (fresh extract or all grain) that is low in IBU's. Iso-alpha acids can inhibit many species and strains of LAB. Keeping the wort less than 6 IBU's is recommended in general, unless the brewer has information about their LAB culture that indicates that they can tolerate more. Mash hopping is one technique that can be used to limit the IBU's by about 70% [2]. If hops are not required (commercial brewers may be required to use hops, while homebrewers aren't), they can be completely excluded from the recipe. This method has been used by some brewers before a lot was known about sour brewing microbes and before some of the more current techniques were popularized (such as Sour Worting, or the other methods mentioned in this article). This method is best described by the following: Brewer X has a beer, and perhaps that beer didn't come out the way they wanted, or perhaps there is some other motivation, but Brewer X decides that they want this beer to be sour. Great idea, right? Perhaps. Lactobacillus tends to prefer simple sugars, which are required for lactic acid production. Pediococcus can break down some of the larger chain sugars that are left over in the beer from the Saccharomyces fermentation, but there may not be enough of those sugars to create even a moderate level of acidity. If the beer contains more than 6 IBU's, the bacteria may be largely inhibited. The Brettanomyces in general should create a nice range of flavors (see Funky Mixed Fermentations) in secondary, so this could benefit the beer. However, due to the lack of sugars, finished beers which a brewer may attempt to sour often do not get very sour at all. Some brewers have reported good results with this technique (particularly professional brewers who use barrels; see "American Sour Beers" by Michael Tonsmeire for more information), but in general if the brewer is going for a truly sour beer, it is better to use another method.

If this method is used, it generally requires 6-12+ months, which is required for the Brett and Pedio to break down the remaining complex sugars.

Wort Production

The grain bill and production for the wort doesn't have to be complex. For sour blonde ales a simple grain bill of about 70% Pilsner malt and 30% malted wheat can be used (these can be replaced by Pilsner and wheat unhopped extracts for the extract brewer. See Lambic Brewing by Steve Piatz for a good extract recipe). Some crystal and a small amount of roasted malts an be used for sour brown ales. Some higher chain sugars or even starches can be included for beers that will be aged for a long time and include Brettanomyces, or Brettanomyces and Pediococcus (Pediococcus generally should not be used without Brettanomyces. See the Pediococcus page for more details). Performing a Turbid Mash is the traditional way to include starches in the wort, however other methods such as steeping some oats or flaked wheat during the boil can also impart starches that won't be converted to sugars by the mash [3]. This step is completely optional, however it may be very beneficial to make sure some higher chain sugars or starches are available in the wort if the brewer wants to rely on Pediococcus for producing most of the acidity. Extract brewers can use 0.25 lbs. (0.11 kg) of Maltodextrin [4], or hot steep a pound of flaked wheat, flaked oats, or carapils malt.

Bug Inoculation

Once the wort is produced and chilled, the mixed culture can be pitched as normal. If using a mixed culture from a commercial yeast lab, it is usually recommended to not make a yeast starter with it because the starter will throw off the intended ratios of the microbes. Instead of buying a single mixed culture, a brewer can create their own mixed culture by combining their own ratios from single cultures of yeast and bacteria. A single mixed culture can be supplemented by adding pure cultures from different yeast labs as well. Another suggestion that often helps produce a higher quality sour beer is to supplement the mixed culture with a Commercial Sour Beer Inoculation. In general, the more diversity of microbes, the more complex a sour beer can potentially be. Using a Sour Worting method in conjunction with this method can help increase acidity that may not otherwise be produced by some commercial blends (Wyeast Roeselare is known for this characteristic, for example).

Aging is generally required for mixed fermentations that include Brettanomyces. Expect an aging time of at least 9 months, but preferably 12-18 months or longer

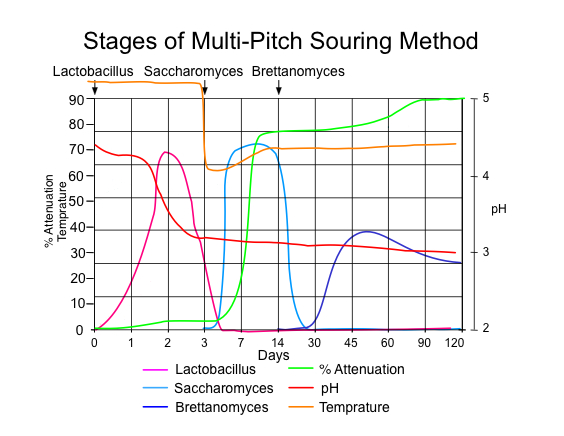

Stages of Fermentation

Modern Method-Fast Fermentation

For sour beers that only use Lactobacillus and Saccharomyces, sometimes also known as Quick Sours, aging is optional. Sour beer should be aged in an environment that minimizes high temperatures and exposure to oxygen. Drastic temperature fluctuations and changes in atmospheric pressure will cause a vacuum inside of the fermentation vessel causing water airlocks to "suck back" air into the fermenter. This could potentially contribute to acetic acid and ethyl acetate (nail polish aroma in high concentrations) production by Brettanomyces, however the development of a pellicle can help protect against this. Filling the carboy to the neck will also help minimize the surface area of the beer that can be exposed to air. Avoid over sampling the beer (once every 3 months at the very most). It should also be noted that micro-oxygenation is helpful for creating certain flavors in sour beer, and many homebrewers have reported not having any issues with over exposure to oxygen using water-based airlocks.

Wort Production

Multi-Stage Fermentation

Matt Miller outlines a three stage fermentation process on his blog article Understanding, Brewing, and Blending a Lambic Style Kriek [7]. See the article for a much more detailed process. Matt was also interviewed about his process by James Spencer on the BasicBrewing Radio podcast. In summary, his process is as follows:

- Produce a low hopped wort (see the Standard Method above).

- After boiling the wort, cool it to 110-120°F (43.3-48.9°C), and run it into the fermenter.

- If possible, purge the fermenter of oxygen with CO2. Pitch a pure culture of Lactobacillus, and if possible hold the temperature between 110-120°F (43.3-48.9°C) for 2-4 days (see the Souring in the Primary Fermenter page for more details).

- After 2-4 days, cool the wort to 65-70°F (18.3-21.1°C), oxygenate the wort, and pitch a starter of Saccharomyces.

- After primary fermentation has finished, transfer the beer to a secondary vessel for aging.

- Add one or more cultures of Brettanomyces. Optionally, also pitch a culture of Pediococcus and/or bottle dregs from commercial sours (see Commercial Sour Beer Inoculation for more details on using commercial bottle dregs). For more funky Brett flavors, do not make a starter for the Brett.

- Age for 6-18 months, or longer if desired.

- For the last two months of aging, fruit, spices, and/or oak can be added directly into the fermenter. Also consider Blending with other sour beers.

Finishing Mixed Fermentations

Reusing a Sour Yeast Cake

Reusing a sour yeast cake can often provide great results. Brewers have reported success repitching on very old yeast cakes (2 years) without getting off flavors from yeast autolysis. After several months, Saccharomyces tends to die off due to the low pH in a sour beer. The bacterias and Brettanomyces tend to survive the lower pH, and their cell counts can be high in even an old yeast cake. By pitching new wort on an old sour yeast cake, these microbes (particularly the Lactobacillus) have access to the simple sugars in the wort [8]. In general, washing the yeast cake is not necessary.

Some brewers will harvest a certain amount of trub from their fermenters (500ml for example), and use only this amount to inoculate a new batch of beer. This will allow the brewer to control the amount of dead trub material that goes into the fresh beer. Michael Tonsmeire often advises that the brewer also pitch a fresh culture of Saccharomyces [9].

Some brewers have good success reusing a yeast cake or a portion of a yeast cake by leaving the wort in contact with the old yeast cake for 3-4 days. After 3-4 days, a fresh culture of Saccharomyces is pitched to finish the fermentation. The 3-4 day head start gives the souring bacterias a head start and results in a low pH beer.

As with all methods, the species and strains of the microbes being used should always be taken into consideration. Experimentation and repeated processes should be carefully employed by the brewer in order to find the best results for their cultures. For example, using different strains of Saccharomyces cerevisiae as the primary fermenter can produce widely different results.

Adding Fruit

When to Bottle

Bottling

References

- ↑ BJCP 2014 Style Guidelines Draft.

- ↑ Putting Some Numbers on First Wort and Mash Hop additions. David Curtis. NHC 2014.

- ↑ Homebrewtalk Discussion started by Amos Brown aka 'Metic'

- ↑ Lambic Brewing. Piatz, Steve. Brew Your Own Magazine. October, 2004.

- ↑ Tonsmeire, M. (2014). American Sour Beers. Brewers Publications

- ↑ Sparrow, J. (2005). Wild Brews: Beer Beyond the Influence of Brewer's Yeast. Brewers Publications

- ↑ Understanding, Brewing, and Blending a Lambic Style Kriek. Miller, Matt. Retrieved 1/24/2015.

- ↑ Tonsmeire, Michael. The Mad Fermentationist. Brewing Sour Beer at Home. Last paragraph in the "Inoculation" section. Retrieved 2/19/2015.

- ↑ Tonsmeire, Michael. The Mad Fermentationist. Brewing Sour Beer at Home. Comments section. Retrieved 2/19/2015.